- HOME

- ABOUT US

- PRODUCTS

- LOW VOLTAGE

- Cables

- Circuit Breakers and Disconnectors

- Control and Protection Devices

- DinRail Devices

- Industrial and Civil Wiring Accessories

- Distribution and Automation Panels

- Cable Ducts Systems

- Conduits and accessories

- Protection systems

- Fan and Ventilation Systems

- Lamps and Lighting Accessories

- Cable Accessories

- MEDIUM VOLTAGE

- FIXING SYSTEMS

- SPECIAL SYSTEMS & ICT

- AIR CONDITIONING

- MHI – Residential

- MHI – Commercial

- MHI – VRF Systems

- MHI – Termal

- Q-Ton Heat Pump

- MHI – Hydrolution

- MHI – Controlers

- HOKKAIDO – Residential and commercial R32

- HOKKAIDO – Vrf systems R410A

- HOKKAIDO – Heating and domestic hot water

- HOKKAIDO – Portable air conditioner

- VORTICE – Residential Ventilation

- VORTICE – Electric Heating

- WAYEL ELECTRIC BIKES

- LOW VOLTAGE

- LIGHTING

- OUTLET

- POWER TOOLS

- STORES

- MEDIA

HYDROLUTION

Air-to-water heat pump for heating, cooling and for the production of domestic hot water.

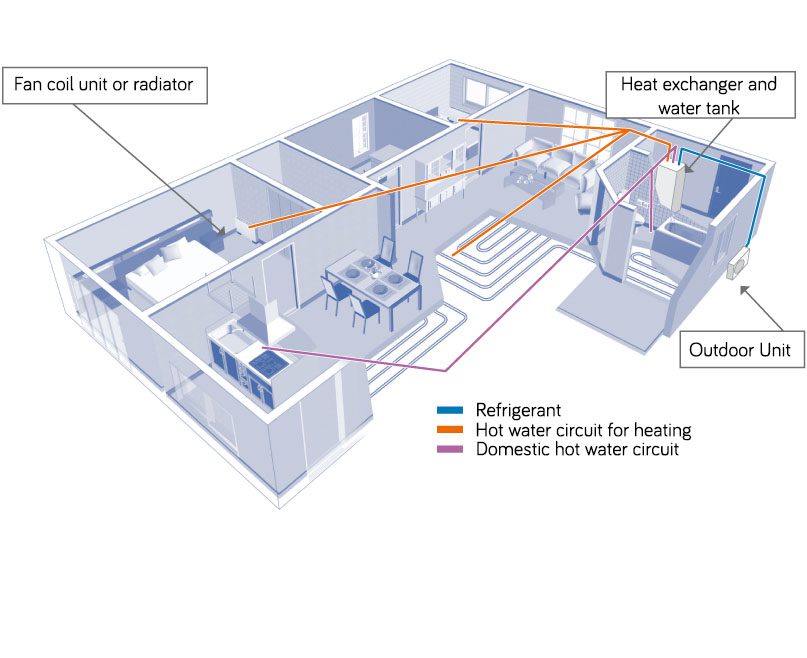

Thanks to the integration of a hot water heater, immersion heater, circulating pump and climate system within the indoor unit, the Hydrolution range is one of the safest, most economical and environmentally friendly options available today.

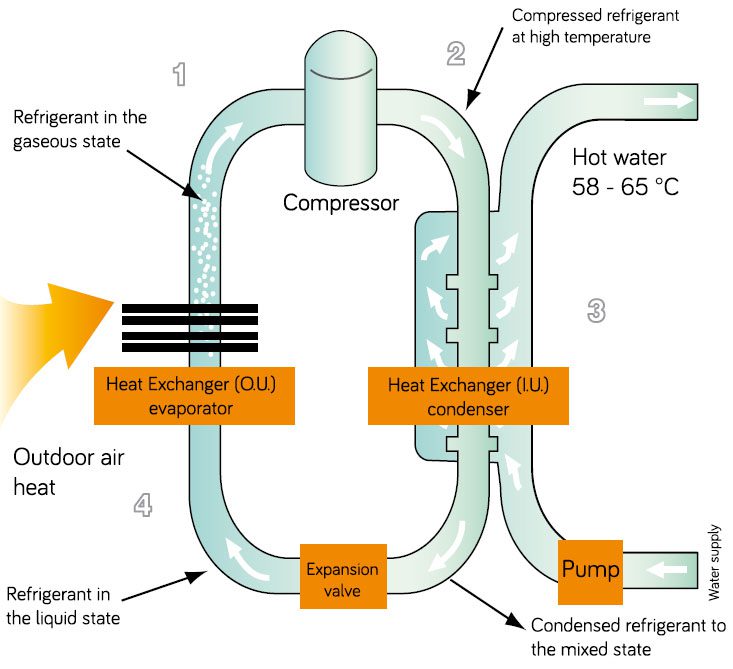

The heat energy is generated from the outdoor air through the outdoor unit, and is transferred to the indoor unit via refrigerant circulation within a closed piping system. This eliminates the need for boreholes and coils in the ground for conventional systems. A heat exchanger in the indoor unit uses hot refrigerant to heat hot water stored in a tank.

Benefits offered by the Hydolution heat pump include:

recovers the heat from the outside air (heat source) by the refrigerant gas, and increases its temperature through the compression process.

In Cooling mode, the process is just the opposite: the refrigerant recovers heat energy from water and releases it to the outdoor unit, according to the principles of heat pump.

Thanks to the presence of a temperature sensor, the indoor unit determines whether the outdoor unit should be operational. In case of extra demand of heat energy, the auxiliary immersion heater or any other heat generators connected to the system, can start operation.

compressed at high temperature, is conveyed towards the indoor unit.

In Cooling mode, the process is just the opposite: the refrigerant recovers heat energy from water and releases it to the outdoor unit, according to the principles of heat pump.

Thanks to the presence of a temperature sensor, the indoor unit determines whether the outdoor unit should be operational. In case of extra demand of heat energy, the auxiliary immersion heater or any other heat generators connected to the system, can start operation.

transfers heat energy to water, which subsequently distributes it to the system.

In Cooling mode, the process is just the opposite: the refrigerant recovers heat energy from water and releases it to the outdoor unit, according to the principles of heat pump.

Thanks to the presence of a temperature sensor, the indoor unit determines whether the outdoor unit should be operational. In case of extra demand of heat energy, the auxiliary immersion heater or any other heat generators connected to the system, can start operation.

The air / water heat pump MHI is a revolutionary energy recovery system that uses the heat of the air as a renewable source. Notoriously, the traditional boilers produce energy by combustion, that is, a process which provides strong emissions of CO2.

The air / water heat pump MHI, by virtue of the energy savings that characterizes the entire operating process, consumes only a small part of the energy that makes the dwelling. This reduces the overall emission of CO2 into the environment.

Internal units are perfectly integrated in an air conditioning system which also includes the insertion of:

| Type | 8 kW | 11 kW | 16 kW |

|---|---|---|---|

| Indoor Unit | HMA 100V1 | HMA 100V1 | HMS 140VA1 |

| Storage Tank | Integrated in the internal hydronic module | Integrated in the internal hydronic module | HT30 (only for heating) - MT300 & MT500 (heating and domestic water) |

| Outdoor Unit | FDCW 71VNX-A | FDCW 100VNX-A | FDCW 140VNX-A |

| External power supply unit | 1-230V 50Hz | ||

| Nominal Power on heating (kW) A7/W35 | 8,3 (2,0 ~ 8,3) | 9,2 (3,5 ~ 10,0) | 16,0 (4,2 ~ 16,0) |

| Nominal Power on heating (kW) A-7/W35 | 7,3 | 8,0 | 12,3 |

| Nominal Power on heating (kW) A7/W45 | 8,0 (3,0 ~ 8,0) | 9,0 (3,5 ~ 11,0) | 16,0 (5,8 ~ 16,0) |

| Power Consumption on heating (kW) A7/W35 | 2,03 | 2,15 | 3,81 |

| Power Consumption on heating (kW) A-7/W35 | 2,81 | 2,84 | 4,71 |

| Power Consumption on heating (kW) A7/W45 | 2,40 | 2,62 | 4,83 |

| COP (W/W) A7/W35 | 4,08 | 4,28 | 4,20 |

| COP (W/W) A-7/W35 | 2,60 | 2,82 | 2,61 |

| COP (W/W) A7/W45 | 3,33 | 3,44 | 3,31 |

| SCOP (W/W) W35 | 3,78 | 4,18 | 4,20 |

| Average climate | 151% | 167% | 168% |

| Energy efficiency class on heating | A++ | A++ | A++ |

| SCOP (W/W) W55 | 3,03 | 3,20 | 3,38 |

| Average climate | 121% | 128% | 135% |

| Energy efficiency class on heating | A+ | A++ | A++ |

| Energy efficiency class ACS | A | A | A |

| Nominal Power on cooling (kW) A35/W18 | 10,7 (2,7 ~ 10,7) | 11,0 (3,3 ~ 12,0) | 16,5 (5,2 ~ 16,5) |

| Nominal Power on cooling (kW) A35/W7 | 7,1 (2,0 ~ 7,1) | 8,0 (3,0 ~ 9,0) | 11,8 (3,1 ~ 11,8) |

| Power Consumption on cooling (kW) A35/W18 | 3,19 | 3,04 | 4,36 |

| Operating Limit (environment temp.) on heating | -20 ~ +43°C | ||

| Operating Limit (environment temp.) on cooling | 15 ~ +43°C | ||

| Operating Limit (water temp.) on heating | 25 ~ +58°C | ||

| Operating Limit (water temp.) on cooling | 7 ~ +25°C | ||

| Domestic hot water producibility (12 liter/min) | 270 | 270 | see separate tanks |

| Domestic hot water producibility (16 liter/min) | 200 | 200 | see separate tanks |

| Max. tubes distance (m) | 30 | ||

| Unit | 8 kW | 11 kW | 16 kW |

|---|---|---|---|

| Indoor Unit | |||

| Height (mm) | 1760 (+20÷50 adjustable feet) | 1004 | |

| Width (mm) | 600 | 511 | |

| Length (mm) | 650 | 360 | |

| Auxiliary Electric Resistance | A total of 9 kW (3 levels of intervention: 2-6-9 kW) 1-230V 50Hz / 3-400V 50Hz | See separate tanks | |

| Tank Storage Volume (liter) | 270 ±5% | See separate tanks | |

| Hot Water Coil Volume (liter) | 14 | See separate tanks | |

| Heat Exchanger | ALFA LAVAL - brazed stainless steel plate AISI 316 | ||

| Volume of the expansion vessel (liter) | - | 18 | |

| Pump Inverter (Type - liter/h) | WILO/Yonos PARA 7.0 PWM - 1600 | WILO/Yonos PARA 7.5 PWM - 2200 | |

| Noise Level db(A) | 35 | 35 | 35 |

| Size of the cooling system pipes (mm) | 22 (DN20) | 28 (DN25) | |

| Size of the hot water pipes (mm) | 22 (DN20) | See separate tanks | |

| Outdoor Unit | |||

| Height (mm) | 750 | 845 | 1300 |

| Width (mm) | 880 | 970 | 970 |

| Length (mm) | 340 | 370 | |

| Weight (kg) | 60 | 74 | 105 |

| Noise Level db(A) | 55 | 58 | |

| Treated Air m3/h | 3000 | 43800 | 6000 |

| Compressor (Type) | Twin Rotary DC Inverter | ||

| Expansion Valve | EEV (electronic) | ||

| Refrigerant Volume (R410A) kg(m) | 2,55 (15) | 2,9 (15) | 4,0 (15) |

| Type | HT30 | MT300 | MT500 |

|---|---|---|---|

| Heating only | Heating & Domestic Water | ||

| Supply | 1-230V / 3-400V 50Hz | ||

| Volume (liter) | 30 | 300 | 500 |

| Hot Water Coil Volume (liter) | - | 14 | 21 |

| Hot Water Producibility (12 liters/min) | - | 320 | 950 |

| Hot Water Producibility (16 liters/min) | - | 230 | 550 |

| Height (mm) | 360 | 1880 | 1695 |

| Width (mm) | 593 | 600 | 760 |

| Length (mm) | 360 | 600 | 876 |

| Weight (kg) | 23 | 110 | 131 |

| Cooling System's pipes diameter (mm) | 28 (DN25) | ||

| Hot Water's pipes diameter (mm) | - | 28 (DN25) | |

| Auxiliary Electric Resistance | A total of 9 kW (3 levels of intervention: 2-6-9 kW) | ||

English

English  Albanian

Albanian